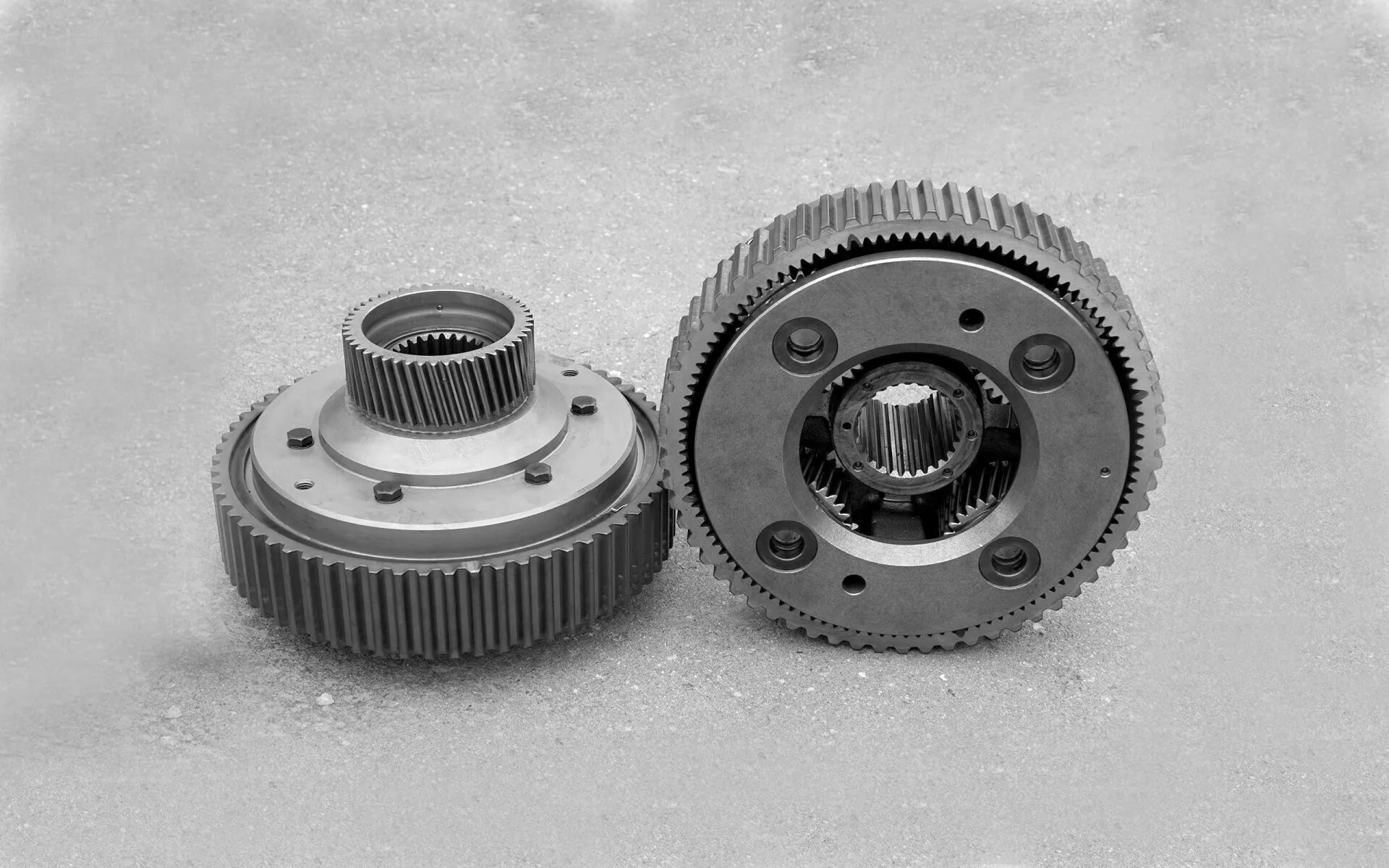

Planetary Gear Units

Planetary Gear Unit Highlights

Project Name and Description:

- Planetary Gear Unit

Industry for Use:

- Home Appliances

Standards Met:

- ISO 9001:2015 Certified

- International Organization for Standardization

- MPIF - Metal Powder Industries Federation

- APMI - American Powder Metal Institute

- ASTM - American Society for Testing and Materials

- AISI - American Iron and Steel Institute

- SAE - Society of Automotive Engineers

Capabilities Applied/Processes:

- Annealing

- Sintering

- Assembly and Brazing

Equipment Used to Manufacture Part:

- Assembly Presses

- CNC Mill

Material Finish:

- Powder Metal

- Oil Impregnated